ESA Open Invitation To Tender AO8937

Open Date: 10/04/2017

Closing Date: 31/05/2017 13:00:00

Status: ISSUED

Reference Nr.: 17.133.04

Prog. Ref.: GSTP Element 1 Dev

Budget Ref.: E/0904-611 – GSTP Element 1 Dev

Special Prov.: BE+GB+LU

Tender Type: C

Price Range: > 500 KEURO

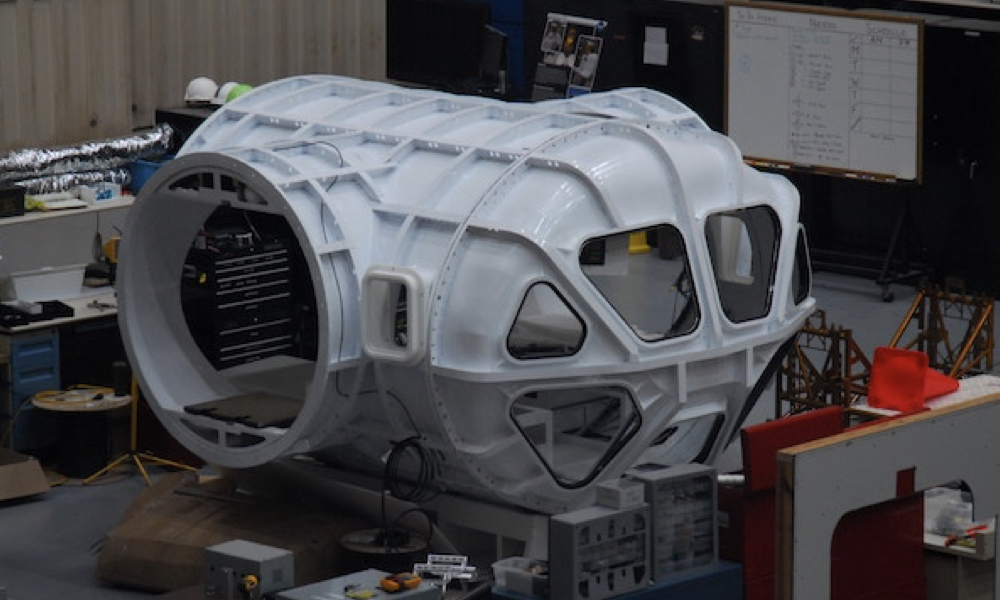

Products: Satellites & Probes / Structures / Primary Structures / Launchers / Structures / Propellant tanks / Orbital Transportation & Re-entry Systems / Structures / Modules structures / Cargo, Separation and distancing, Launch Escape System, Re-entry Module, …

Techology Domains: Materials and Processes / Materials Processes / Advanced Materials Manufacture

Establishment: ESTEC

Directorate: Directorate of Tech, Eng. & Quality

Department: Product Assurance and Safety Department

Division: Materials & Components Technology Divisi

Contract Officer: van Hilten, Linda

Industrial Policy Measure: N/A – Not apply

Last Update Date: 10/04/2017

Update Reason: Tender issue

The current status of AM shows that secondary and ternary structures can be designed, made, qualified and flown using Titanium or Aluminium. These achievements however are not enough to use the technology for highly loaded and critical structures where the benefit would also be very important. In this activity, it is intended to perform all tasks required to guaranty that a fail-safe element of a primary structure can be used in spacecraft and/or launcher applications.The activity will consist of the following tasks:- Selection of the structural element and establishment of the structural requirements- Re-design of the part toward maximising its performances i.e. using design freedom offered by AM technologies- Define an end-to-end materials and process verification route to be adopted asa standard for primary structural applications- Derive a test plan taking in consideration Tasks 1, 2 and 3 and including all the in-process samples, bread-boarding, NDI, controls to closely monitor themanufacturing and assess the materials properties.- Manufacture and test samples according to the test plan derived in Task 3; if needed, perform delta re-design and delta testing.- Manufacture and test at least 3 parts according to final design and assess the reliability of the procedure. This shall be performed by 2 service providers.

If you wish to access the documents related to the Invitation to Tender, you have to log in to the ESA Portal.